Quality control is a system whereby standards in manufactured products are maintained by testing a sample of the output against the specification.

The Problem

Poor quality control can result in non-conformance where a product, service or process does not meet the defined specification or industry standard. A common problem within the manufacturing world is that defects are often not spotted until the end of the manufacturing process. This creates a risk where an entire batch might be produced with flaws, for example, a packet of biscuits might have the incorrect ingredients printed on the packaging for a batch of 2000 units. Non-conformances can negatively impact a company in terms of cost, reputation, efficiency and effectiveness.

The Solution

Ensuring that quality controls are in place is a never-ending task for operations and quality managers. Non-conformance management software is a useful quality tool that helps manufacturing and distribution companies satisfy compliance requirements.

![]()

Non-conformance management is the process whereby the organisation manages quality control issues so that they are identified, documented, evaluated/investigated, segregated and resolved as appropriate. This allows a business to improve profit margins and keep costs lower for the customer, therefore, remaining competitive within the vertical market.

Sage X3 allows operational performance to seamlessly integrate with a production control plan. Up to date work instructions and quality measures can be accessed across the whole business through the solution.

Application

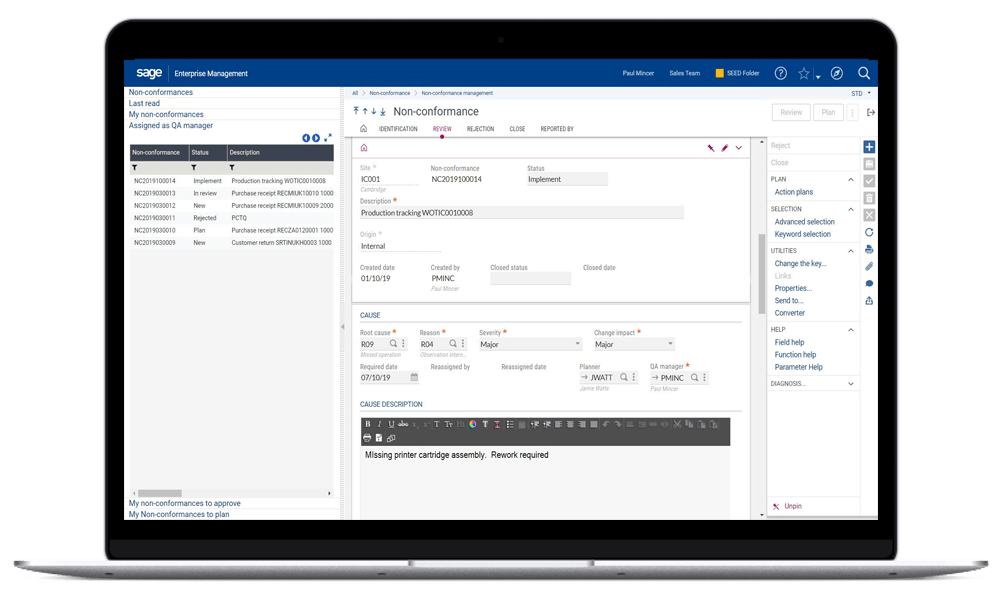

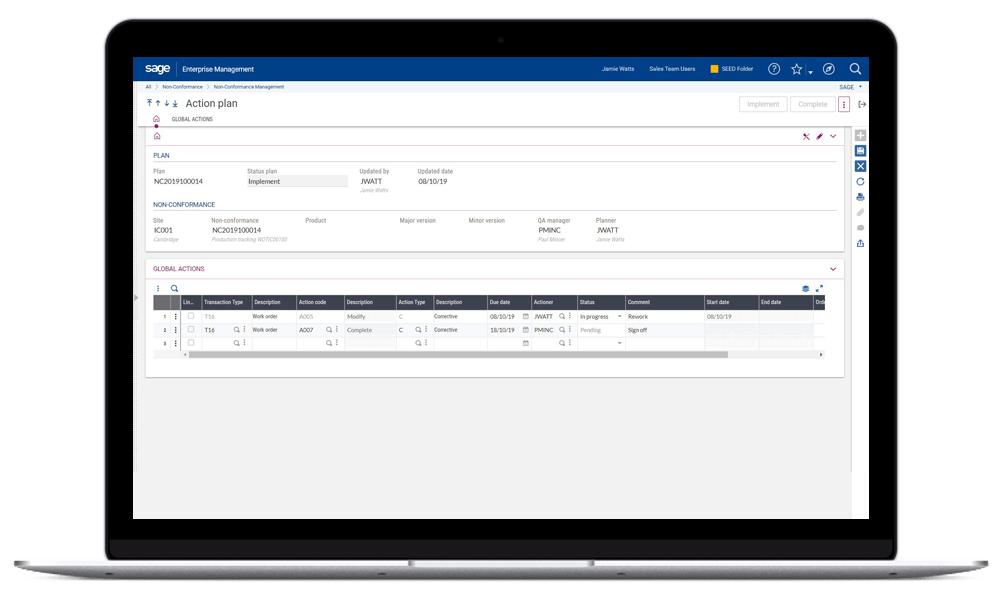

Within Sage X3, users are able to preconfigure parameters and specifications for each item/product in order for the system to effectively manage non-conformance. Preventative and corrective action plans can be created from the Non-conformance Form or directly created without link to a non-conformance. From this stage, actions can be implemented to resolve and avoid future non-conformances.

A manual or paper-based system would not be able to achieve this process to such a precise and efficient standard that an electronic system can. Once a system, such as Sage X3, is in place, it is possible for costs, reputation, efficiency and effectiveness to improve within an organisation.